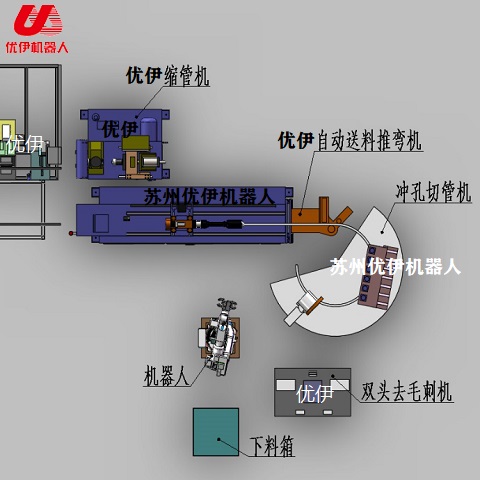

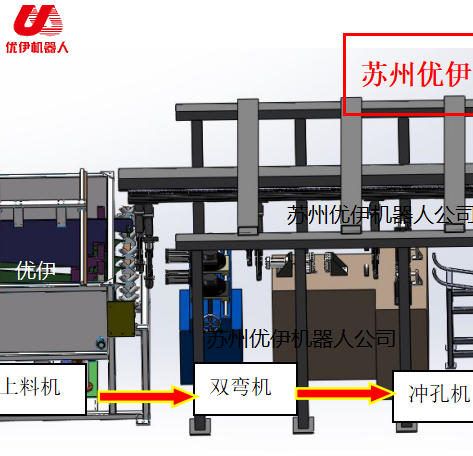

蹦床圆弧管机器人自动生产线(方管)

自动生产线主要技术指标和参数:

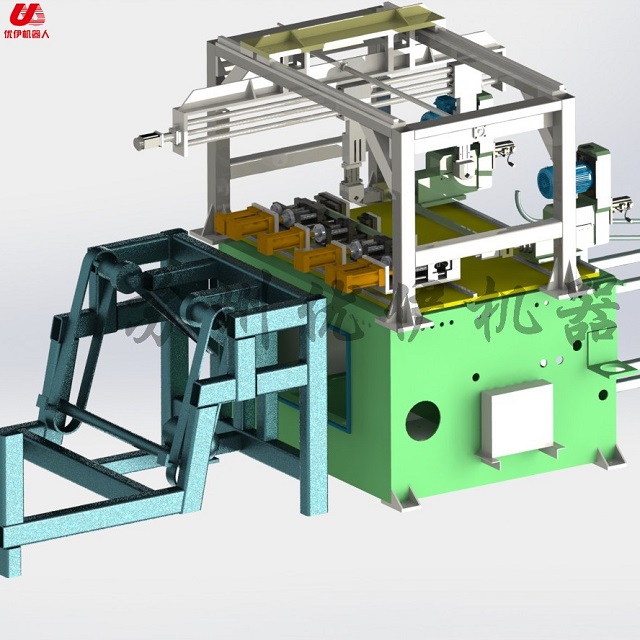

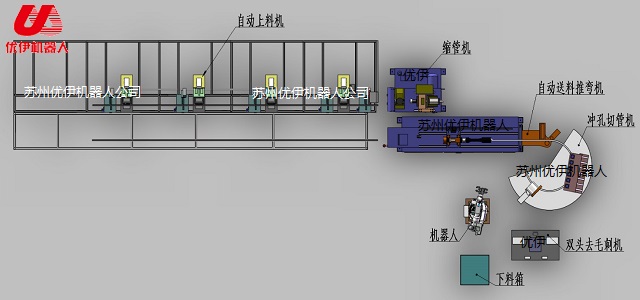

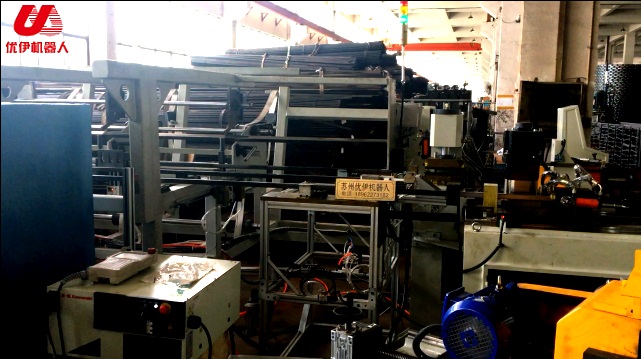

1))上料机指标::5.5-6.5米,双工位,一工位对缩管机缩管,二工位对弯管机进行推弯作业;

2)管件焊缝检测,对管件焊缝进行焊缝定位;

3)缩管机型号:UE-SG40缩管机,6米长管经缩管机缩管后头尾对接送至弯管机推弯;

4)弯管机连续推弯完成后,进行8个孔位一次性冲孔;

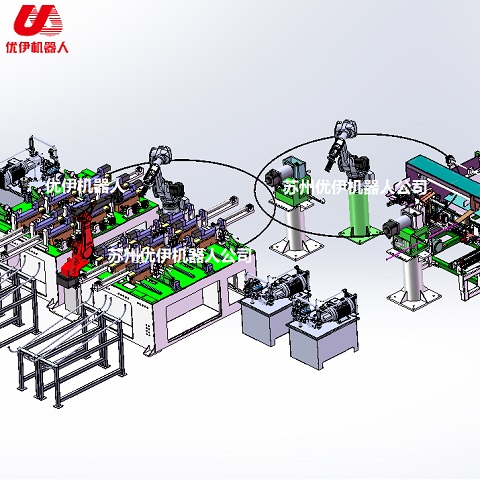

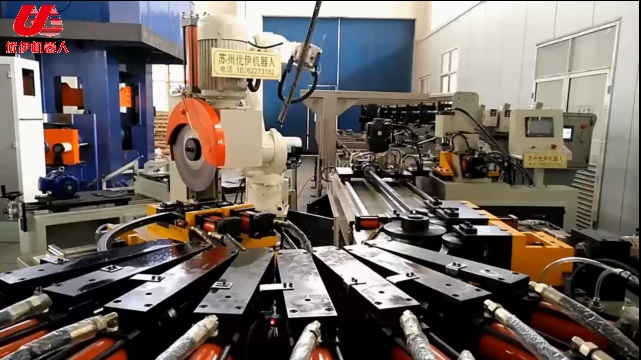

5)全自动切管机进行圆弧管件的锯切(锯切和冲孔同时进行);

6)全自动切管机切管完成后,川崎机器人抓取切好的管料进行卸载管件搬运至双头去毛刺专机;

7)去毛刺专机完成管件两头去毛刺作业后自动下料至料箱。

8)总控系统对系统各单元:自动上料机、自动缩管机、自动弯管机、自动八工位冲孔机、自动切管机、川崎RS-010N机器人、两头去毛刺机全程总控,协调生产!

蹦床圆弧管自动生产线

苏州优伊机器人公司制造

Main parameters of auto work cell :

1) ) feeding machine index: 5.5-6.5 m, double station, one station for the pipe shrinking machine, the second station for bending the bending machine;

2) Weld detection of pipe fittings, weld positioning of pipe welds;

3) Model of pipe shrinking machine: ue-sg40 pipe shrinking machine, the 6-meter long pipe is sent to the pipe bending machine for pushing and bending after being shrunk by the pipe shrinking machine;

4) After the continuous pushing and bending of the pipe bender, 8 hole positions are punched at one time;

5) The automatic pipe cutting machine is used to saw the circular pipe fittings (sawing and punching at the same time);

6) After the pipe cutting is completed by the automatic pipe cutting machine, Kawasaki robot grabs the cut pipe material to unload the pipe fittings and transport them to the double head deburring machine;

7) After deburring, the special machine will automatically discharge the material to the material box after deburring at both ends of the pipe.

8) The main control system controls the whole process of each unit of the system: automatic feeding machine, automatic pipe shrinking machine, automatic pipe bending machine, automatic eight position punching machine, automatic pipe cutting machine, Kawasaki rs-010n robot and two end deburring machine to coordinate production!

苏州优伊机器人科技有限公司

手机:189-1569-8967

邮箱:kevin818@126.com

地址:江苏省张家港市南丰镇振丰路16号