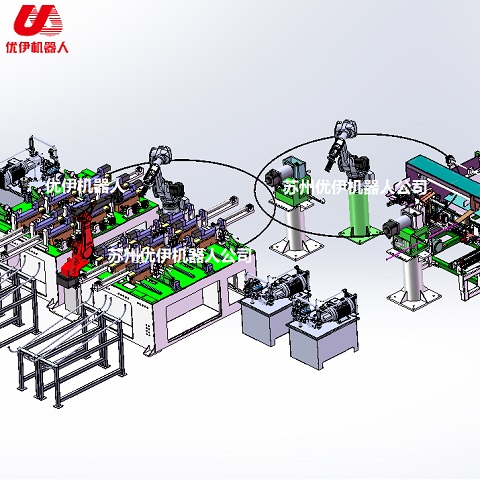

弯管机机器人扶手管自动生产线

弯管机机器人扶手管自动生产线

Auto work cell for chair armrest tube

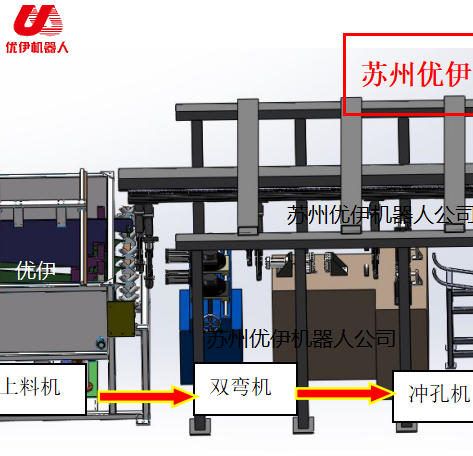

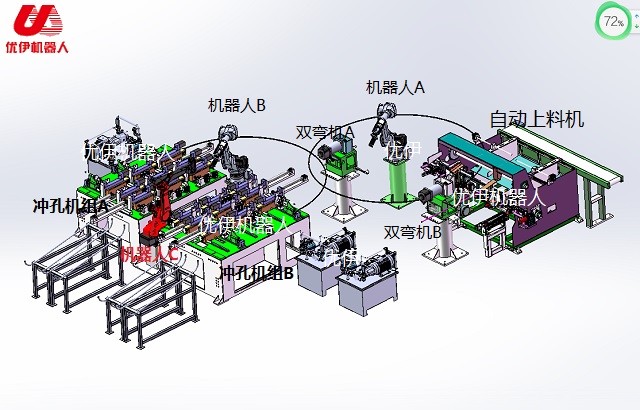

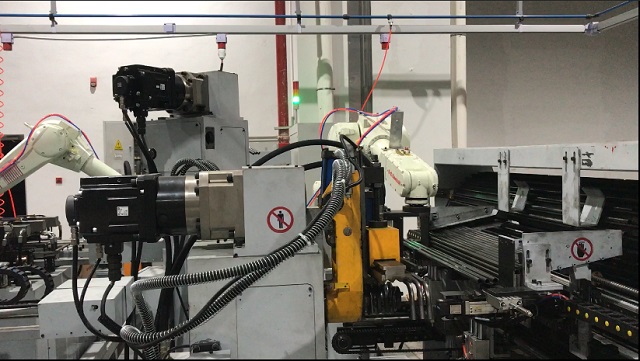

机器人给弯管机上料 Robot feeding tube to bender

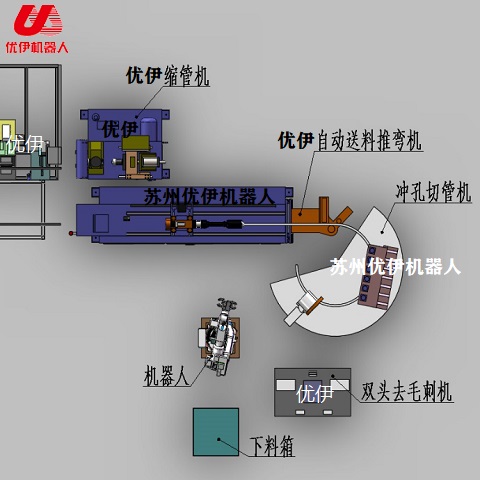

机器人搬运管件到冲孔机

Robot transfer pipe to punching sets

冲孔机对三根管一起冲孔

Punching sets punches three pipes together

机器人卸载成品管件 Robot unloads finished pipe fittings

完成的管 Finished pipe fittings

机器人扶手管自动化生产线(三管并做)

苏州优伊机器人公司制造

主要指标:

1)沙滩椅扶手管项目可以节省人工约6-7人,企业节省人工明显,经济效益明显;

2)加工效率:三根管小于15秒,平均单管节拍<5秒;

3)管件尺寸:直径16mm,长度1200mm

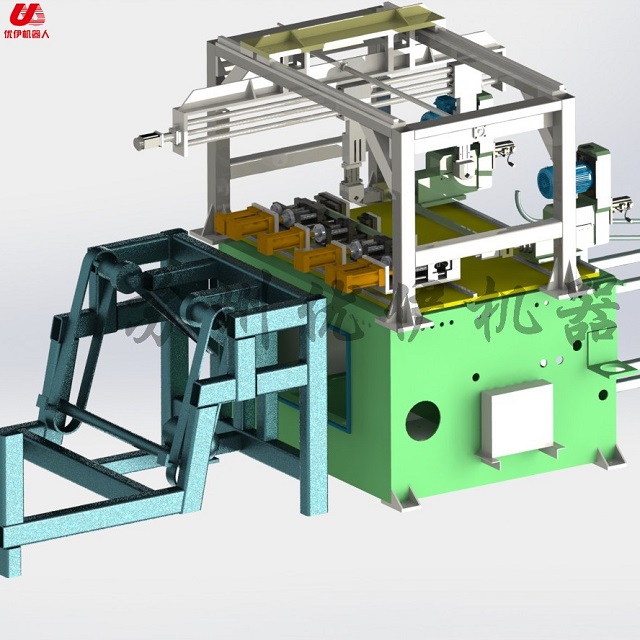

4)加工方式:人工将批量直管放入上料机料仓,传送系统三管一组给伺服自动双头弯管机上料;

5)机器人型号:川崎RS-010N 2台,功能:机器人从双头弯管机一端搬运完成管件到另外一个弯管机头,完成第二弯,第二台机器人从第二个弯管机头搬运管件到(三根管一起)到两组冲孔机;

6)冲孔机对三根管件进行组合冲孔,完成后由下料机器人(国产四轴机器人)卸载成品管件到料架;

7)总控采用自适应智能设计,可以随机器人的速度调整生产节拍;

Main Feature:

1) About 6-7 people can be saved in the project of beach chair armrest tube. The labor saving of enterprises is obvious and the economic benefits are obvious;

2) Processing efficiency: three tubes less than 15 seconds, average single tube beat < 5 seconds;

3) Pipe size: 16mm in diameter and 1200mm in length

4) Processing method: manually put a batch of straight pipes into the feeding machine bin, and the conveying system uses a group of three pipes to feed the servo automatic double head bending machine;

5) Robot model: Kawasaki rs-010n 2 sets, function: the robot carries the pipe from one end of the double head pipe bender to another pipe bending machine head to complete the second bending; the second robot transports pipe fittings from the second bending head to (three pipes together) to two groups of punching machines;

6) The punching machine punches the three pipe fittings in combination, and then the cutting robot (domestic four axis robot) unloads the finished pipe to the material rack;

7) The general control adopts adaptive intelligent design, which can adjust the production rhythm with the speed of the robot;

您如果对这个项目有兴趣可以致电我们:189-6226-9900 (中国)

If you are interested in this project, you can call us: 189-6226-9900 (China),

苏州优伊机器人科技有限公司

手机:189-1569-8967

邮箱:kevin818@126.com

地址:江苏省张家港市南丰镇振丰路16号