U形管自动弯管冲孔自动生产线

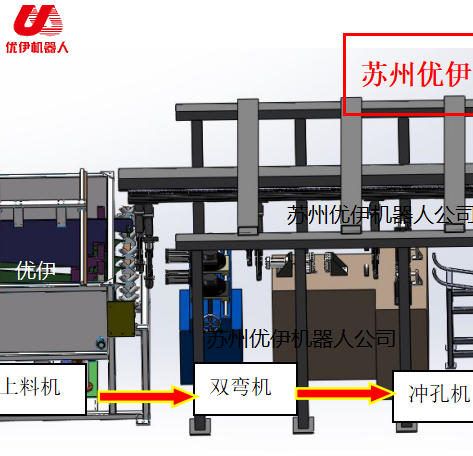

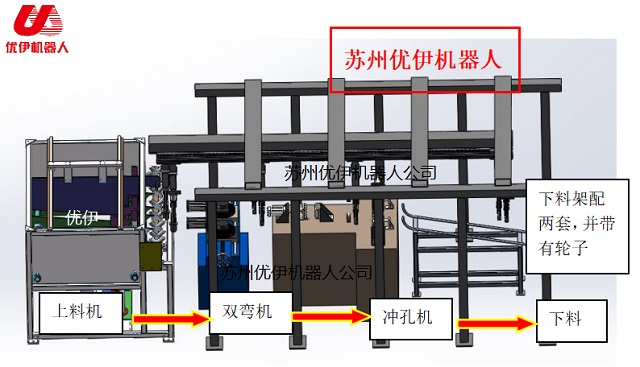

U形管自动冲孔生产线3D示意图

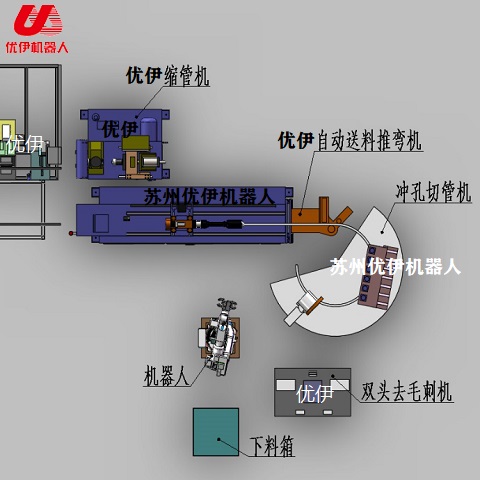

U形管自动弯管冲孔生产线运行

苏州优伊机器人公司制造

U形管自动生产线主要特点:

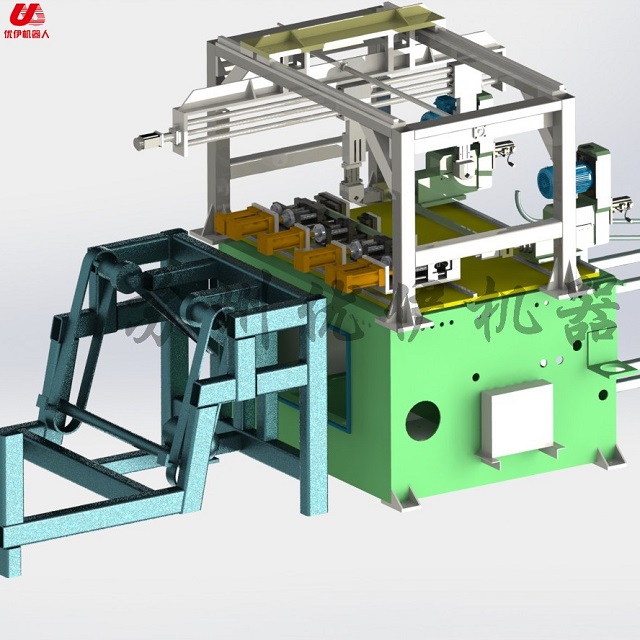

1)主要设备:直管自动上料机、桁架自动搬运模块、自动焊缝检测机构、三菱伺服电机控制双头弯管机、可调节孔距自动冲孔机、自动压弯机(选配)、下料架(可选配智能下料架)。

2)弯管前直管长度:1.8-2.1M

3)管径:22-26mm

4)冲孔孔径范围:4-8mm,冲孔数量:8-11个(也可以选择钻孔,可以定制);

5)自动上料,桁架机械臂自动抓取管件至双弯机(三菱伺服控制),进行双弯弯管作业;

6)双弯弯管完成后,桁架机器手抓取U形管件至冲压专机;

7)冲压专机对11个孔位(包括穿芯冲孔)进行冲孔作业(孔位数量可以定制);

8)冲孔作业完成后,桁架机器手抓取已经完成冲孔的管件至压弯专机进行压弯作业;

9)压弯作业完成后,桁架机器手抓取完成的管件至下料区

10)可用于沙滩椅、钢木家具、行军床、婴儿床等需要U形管的制造和加工。

Main Features

1) Main functions: automatic feeding of straight pipe truss, weld inspection, servo double bending, automatic punching and automatic bending.

2) Length of straight pipe before bending: 1.8-2.1m

3) Pipe diameter: 22-26mm

4) Punching hole diameter range: 4-8mm, punching number: 8-11 (drilling can also be selected, can be customized);

5) Automatic feeding, truss manipulator automatically grabs pipe fittings to double bending machine (servo control) to carry out double bending operation;

6) After the double bend pipe is completed, the truss manipulator grabs the U-shaped pipe fittings to the special stamping machine;

7) The special punching machine can punch 11 hole positions (including core piercing) (the number of holes can be customized);

8) After the punching operation is completed, the truss manipulator grabs the pipe that has been punched to the bending machine for bending;

9) After the bending operation is completed, the truss manipulator grabs the finished pipe fittings to the blanking area

10) It can be used in the manufacture and processing of U-tube for beach chair, steel wood furniture, marching bed, crib, etc.

苏州优伊机器人科技有限公司

手机:189-1569-8967

邮箱:kevin818@126.com

地址:江苏省张家港市南丰镇振丰路16号